Recently, we have seen an increase in enquiries from the battery and fuel cell industry," said Volker Spanier, Head of Industrial Robotics at Epson. - The volume could soon rise to the current level of the photovoltaic industry. The decisive factor for Europe will be the industry's geographical location. For the time being, almost all the equipment suppliers for the gigafactories are located in Asia. Automatica may offer promising approaches, especially for the emerging fuel cell industry."

New requirements for robotics

The applicability of robots raises the question of whether standard robots are even suitable for the production of lithium-ion batteries and fuel cells. What features of four- and six-axis robots are useful in these applications?

Fuel cell manufacturing is a specific industry and would not be where it is today without robots. Each of the 400 to 500 bipolar plates in a given fuel cell stack must be laminated with the utmost precision and care. This requires, for example, robots that are not only extremely fast but also resistant to corrosion. The automatic will show whether robots exist for such specific use cases.

"I am confident that many leading manufacturers offer robots that can meet these requirements," adds Peter Pühringer, Managing Director of Stäubli Robotics Germany. - Stäubli Robotics will be exhibiting four- and six-axis robots for use in hyper-dry environments, as well as special models for operation in corrosive conditions. We are in a position to supply robots for both markets - lithium-ion batteries and fuel cells."

The promising recycling market

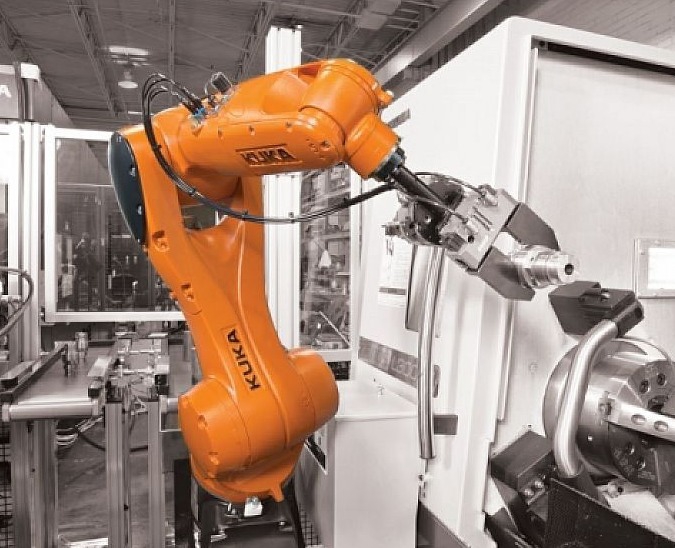

Recycling of electrical devices and batteries is another promising market for robotics and automation. In this context, KUKA has launched an e-waste separation project in Ireland, where human labour is not exposed to the dangers posed by gases and sharp components. WEEE is separated and processed, with the resulting "second life" becoming a valuable resource in the circular economy.

Recycling batteries from electric vehicles is also a promising application. As electric vehicles increasingly take to the roads, the question arises as to what happens to their batteries at the end of their life cycle. According to Dr Joachim Döhner, Chairman of the Board of the Battery Division of the VDMA and Global Battery Sales Director at KUKA, "automating battery dismantling and the recovery of valuable materials will create new know-how and open up new business segments for robotics".

Mandatory sustainability

Climate-neutral production trends and new applications for robotics and automation are expected to be the subject of heated debate at the Automatica trade fair. The new EU Sustainability Directive, which will apply across the EU from 2024, will put the issue of "sustainable automation" even more in the spotlight. The Corporate Sustainability Reporting Directive (CSRD) will require companies above a certain size to submit a sustainability report and assess the sustainability of their production in this context.

Robotics and automation can reduce the environmental footprint: modern assembly lines and robots contribute to related efforts by improving lifetime, energy efficiency and flexibility. Rigidly interconnected assembly lines need to be reconfigured or replaced completely when changing products. "In modern, modular assembly plants, it is usually sufficient to make a few simple modifications and reprogram the robots," emphasizes Frank Konrad, CEO of Hahn Automation and President of VDMA Robotics and Automation, "This is all we need to do, which saves time, resources and energy."